Calculate the cost of making a cutting board

Making a cutting board? Not sure how much wood you'll need or what design you want? Use this simple cutting board calculator to not only see what your cutting board design will look like, but also get an idea on what it will cost.

Step: 2

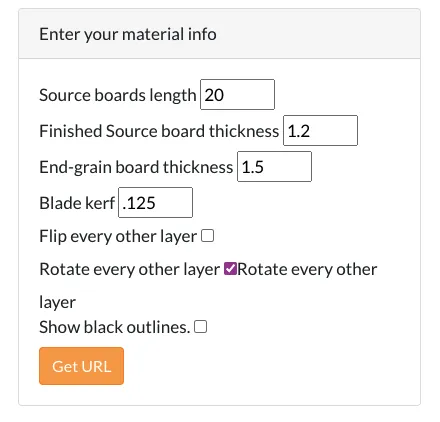

- Source board length is how long all the boards are for your project. Keep in mind that an end-grain cutting board will end up being a lot shorter than your original stock length

- The finished source board thickness is what you expect the actual thickness to be after planing. The calculator assumes 1/4" will be removed during planing/surfacing

- End grain thickness has a large effect on the length of the end product as well as overall durability

- Blade kerf can be adjusted, however a good standard for this calculator is .125 (1/8")

- As you input measurements in the next steps, you will see the rendered output change with the flip/rotate options

- Showing the black outlines will help you visualize the final product.

Step: 3

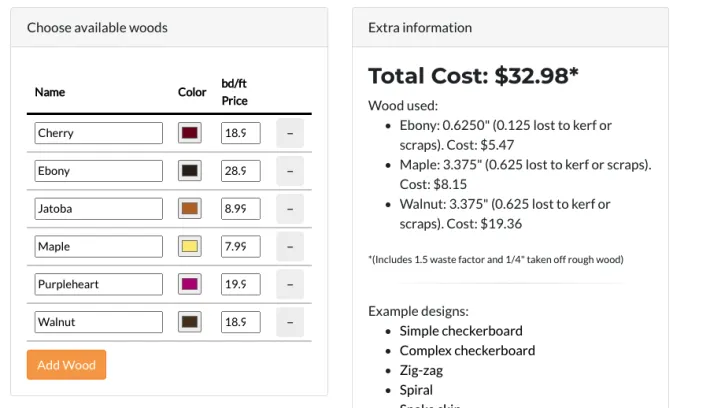

The calculator will come pre-loaded with materials. You can add or remove as needed. Enter in the board foot cost for each material so it can output a rough cost estimate.

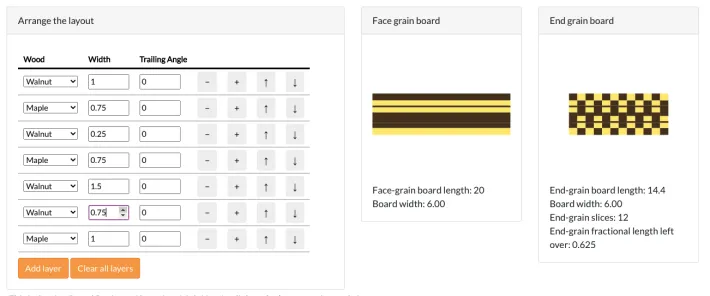

Step: 4

This tool will allow you to use woods in your project at different widths as well as using specific angles to achieve more complex designs. As you update values, you will see the simple renderings update to give you a better idea of what your board will look like. Keep in mind, these are very crude renderings and depending on how you actually make your cut, the final product may not be exact. This is only used as a guide.

Step: 5

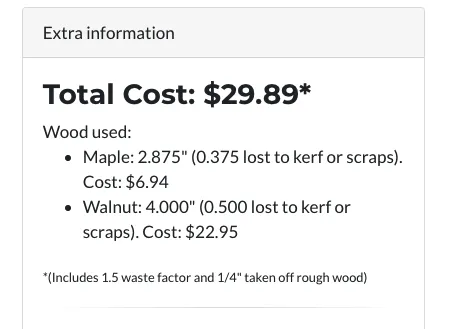

This calculator assumes a waste factor of 1.5. This means that you may have to cut around imperfections or maybe even make a mistake.

As well, it will assume you take off up to 1/4" of wood as you surface your boards. If you don't actually have to surface your boards much, then that's a good thing!

Based on the number of layers for each species of wood, it will also account for kerf (width of your blade).

When you are done, you can click 'Get URL' and a link will appear. Copy that link (bookmark it or share it) so you don't lose your calculations.